|

STEEL COIL CUT TO LENGTH LINE -----FOR LIGHT POLES FABRICATION |

|

|

APPLICATION |

|

It is the first step machine for making light poles if using steel coil. It is for steel coil material uncoiling, leveling, cutting process, to get one straighten steel plate with a certain length. |

| MAIN PARTS OF MACHINE |

|

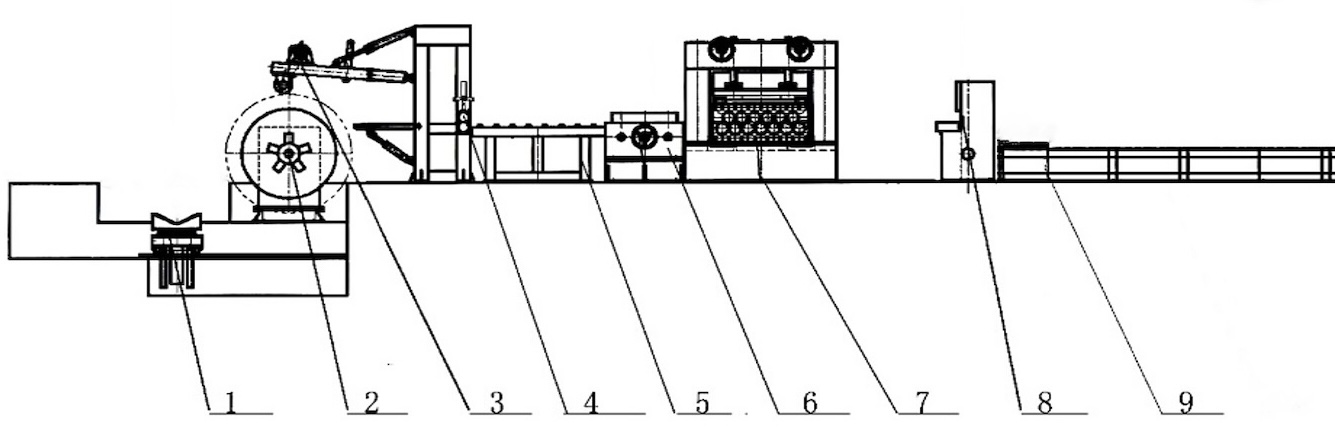

1.STEEL COIL LOADING DOLLY CAR:LOAD THE STEEL COIL TO DECOILER 2.HYDRAULIC DOUBLE HEADS UMBRELLA TYPE DECOILER:ROTATE THE STEEL COIL 3.HYDRAULIC GUIDING-PRESSING,SHOVEL-HEAD:SUPPORTING TO OPEN STEEL COIL TO FEED COIL INTO LEVELING MACHINE. 4.FEEDING ROLLERS: CLAMPING AND FEEDING THE STEEL PLATE FORWARD TO LEVELING MACHINE 5.MIDDLE ROLLING WAY WORKING TABLE 6.GUIDING UNIT:GUIDE THE CENTER OF STEEL PLATE TO THE CENTER OF LEVELING MACHINE. 7.LEVELING MACHINE:STRAIGTHENING THE STEEL COIL INTO STEEL PLATE 8.SHEARING MACHINE:CUT THE STEEL PLATE INTO THE FIX LENGTH 9.BALL TYPE SUPPRTING TABLE:STOCK OR SUPPORT THE STEEL PLATE AFTER SHEARING. |

| REFERENCE PHOTOS | |

|

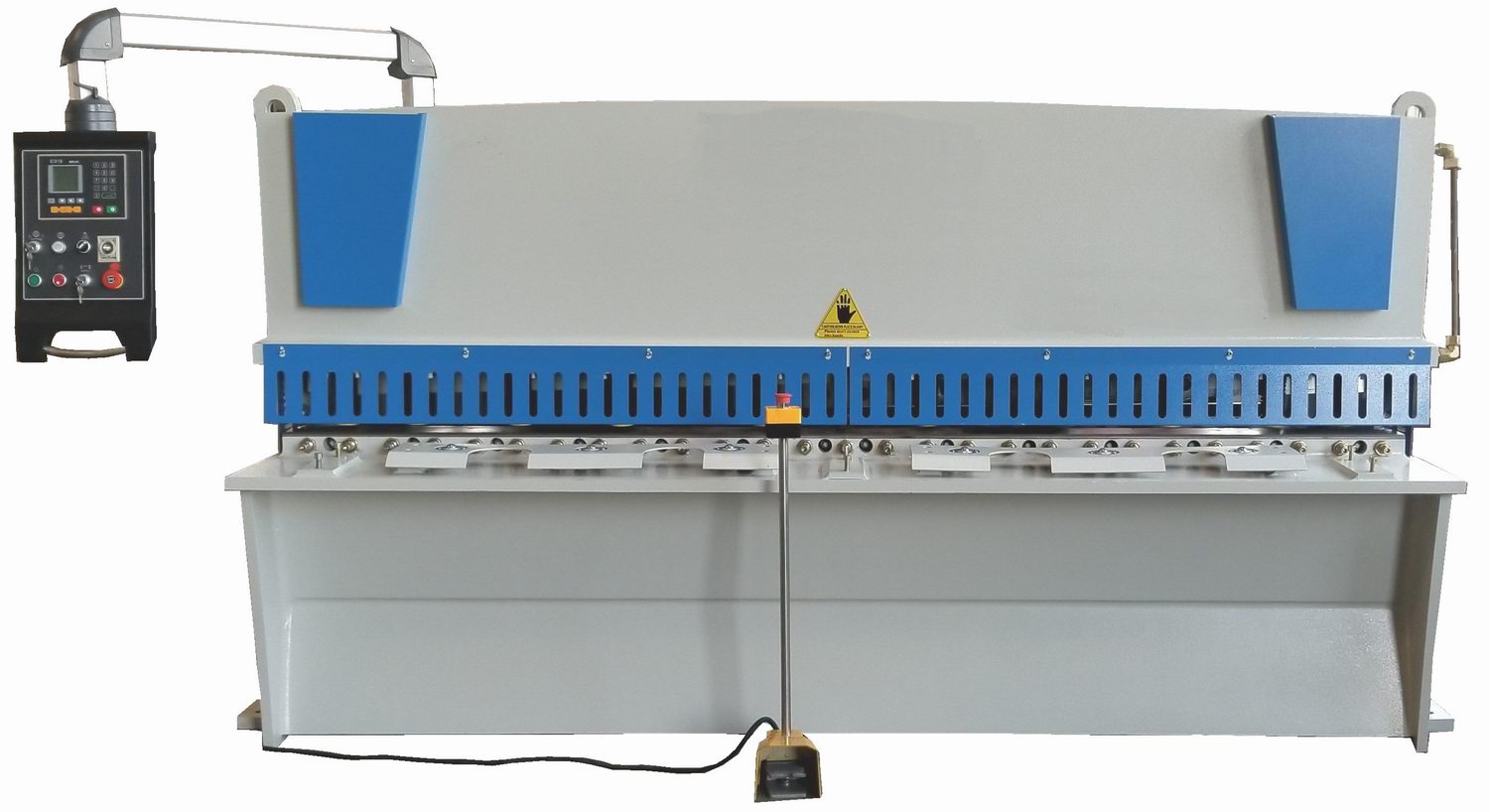

STEEL COIL CUT TO LENGTH LINE MODEL:2-6MMX1600MM (THE THICKNESS OF STEEL COIL FROM 2-6MM WITH MAX WIDTH OF COIL 1600MM) |

|

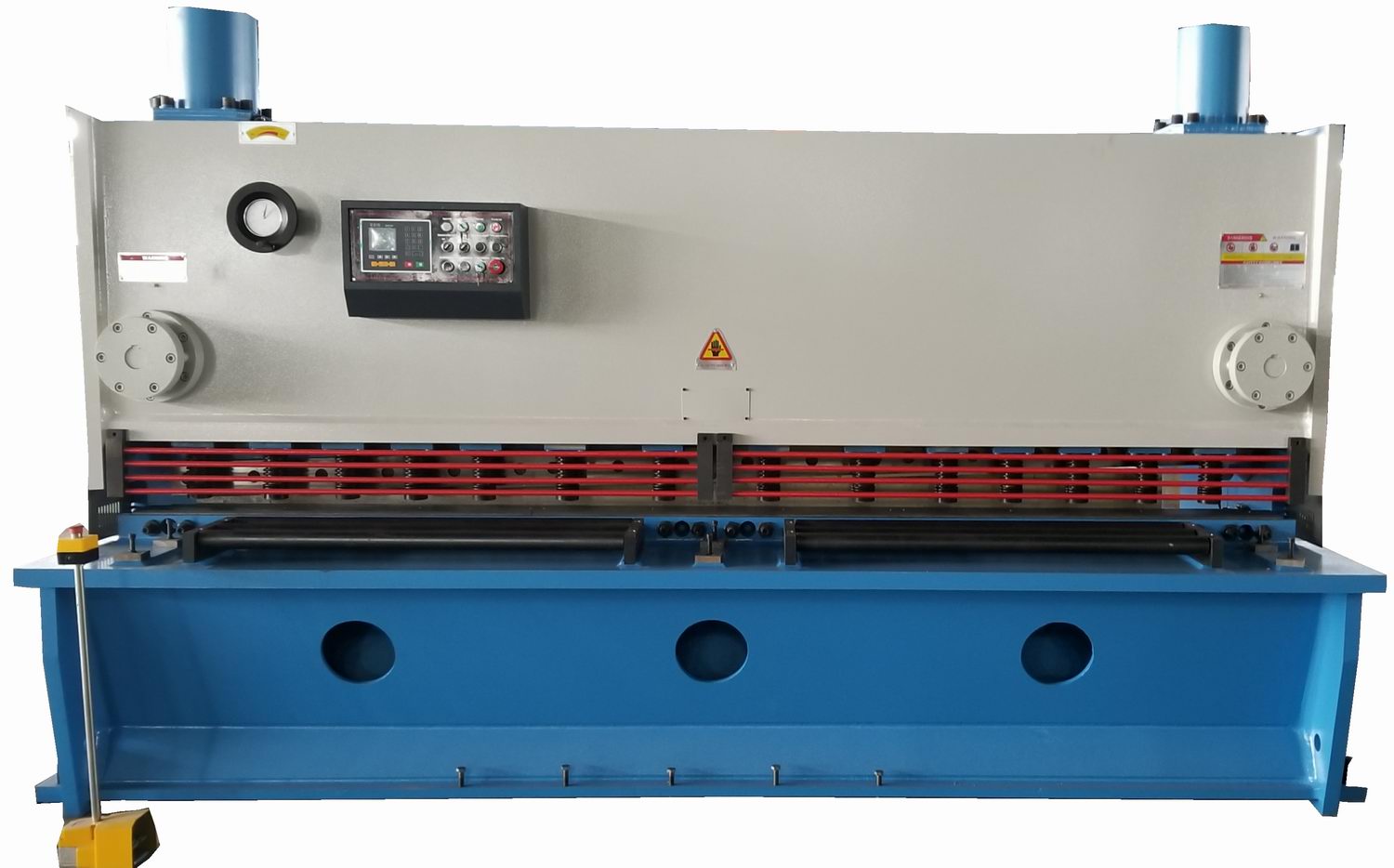

STEEL COIL CUT TO LENGTH LINE MODEL:3-8MMX1800MM (THE THICKNESS OF STEEL COIL FROM 3-8MM WITH MAX WIDTH OF COIL 1800MM) |

|

|

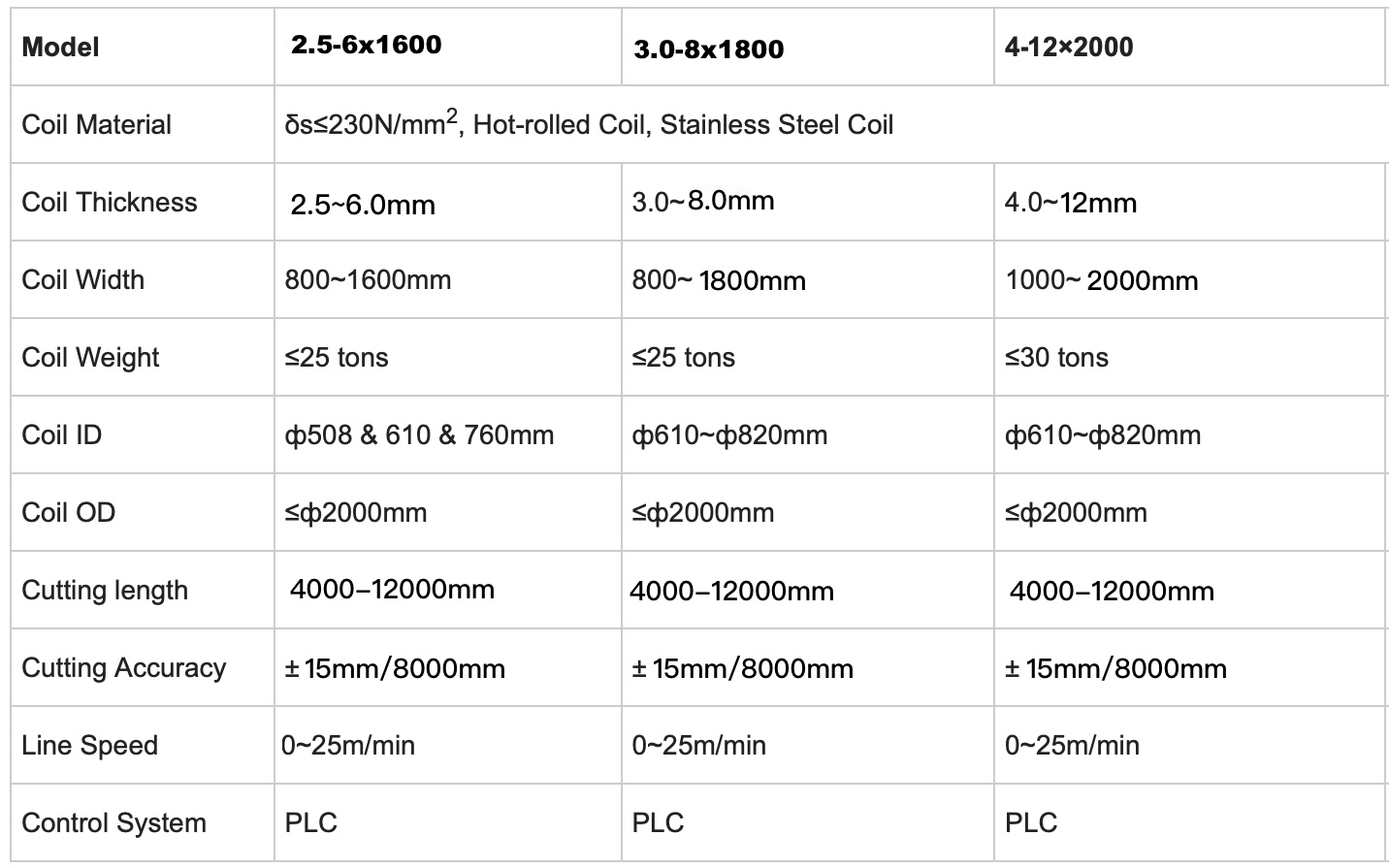

STEEL COIL CUT TO LENGTH LINE MODEL:3-8MMX1800MM (THE THICKNESS OF STEEL COIL FROM 3-8MM WITH MAX WIDTH OF COIL 2000MM) |

| PARAMETERS |

|