|

LIGHT POLE SHUT-WELDING MACHINE|LIGHT POLE WELDING MACHINE|POLE WELDING MACHINE |

|

|

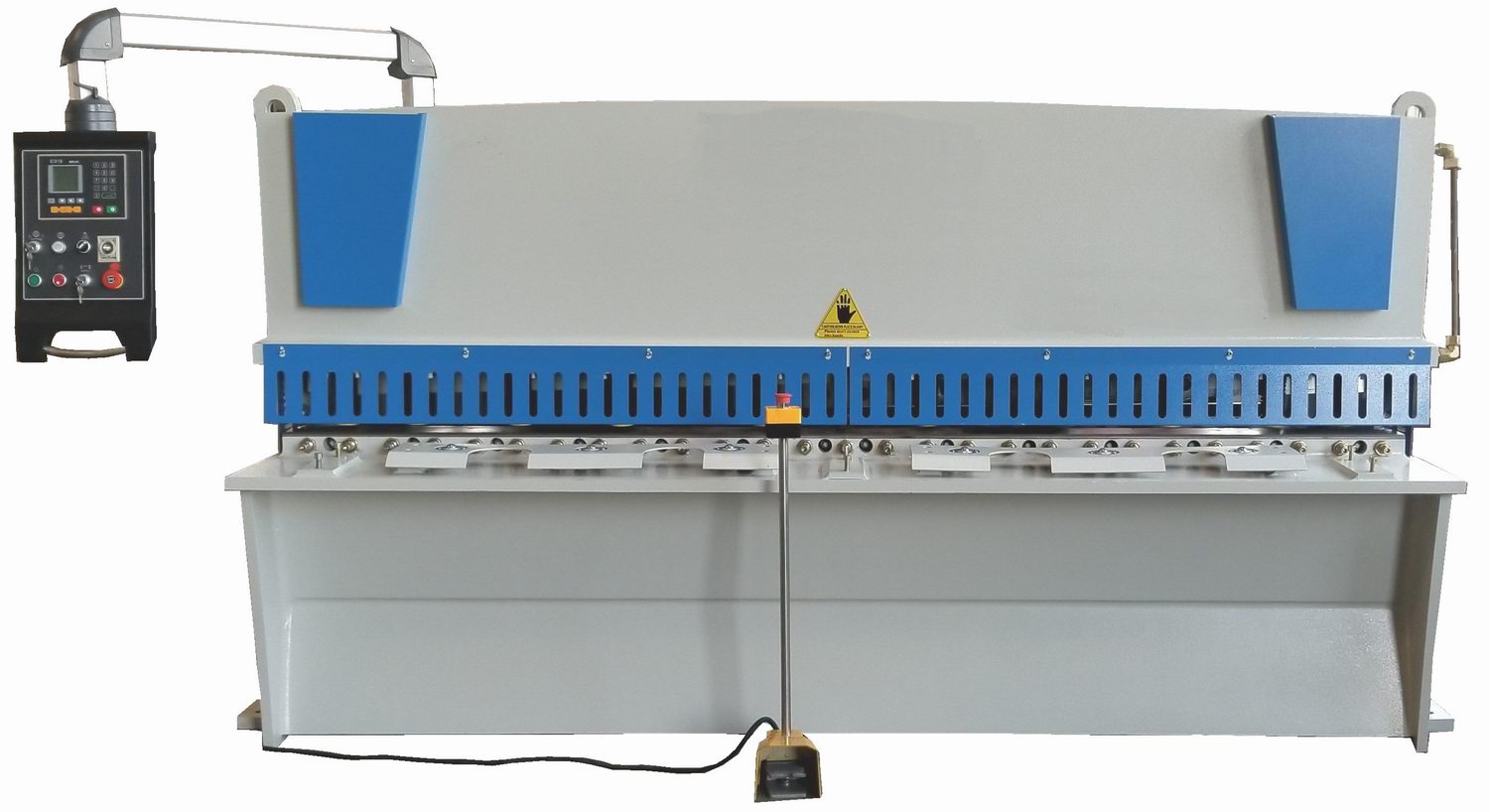

Light pole welding machine, pole welding machine, light pole shut-welding machine which is used to close and welding light pole column.It can do octagonal pole welding and conic pole welding automatically. |

||

|

APPLICATION AND USAGE: 1.WELD THE CONIC LIGHTING POLE 2.WELD THE OCTAGONAL POLE 3.MAX WELDING LIGHTING POLE CAN BE 550MM 4.WELDING LENGTH:8,12,14M (CUSTOMERIZED) 5.CO2 WELDING AND SUBMERGE WELDING TWO FUNCTIONS |

MAIN STRUCTURE: >LONG WORKING TABLE >POLE PULLING DOLLY >8 SETS CLOSING FEET >MAIN WELDING HEAD >BACK LIGHTING POLE SUPPORTE >WELDING FLUX RECYCLE SYSTEMADVANTAGE |

ADVANTAGE: 1.AUTO CLOSE AND WELD THE LIGHTING POLE,SAVE LABOR. 2.CO2 AND SUBMERGE WELDING TWO FUNCTIONS 3.CAN WELDING CONIC AND OCTAGONAL POLES BOTH. 4.8 CLOSING FEET CAN AVOID SCRATCH AND KEEP GOOD 5.WELDING SPEED IS ADJUSTABLE |

|

|

|

| 8 SETS POLE CLOSING FEET |

|

BACK SIDE POLE SUPPORTING DEVICE AND MOVING GUIDER |

|

|

|

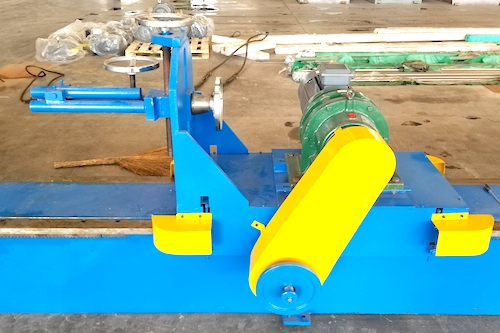

| POLE CLAMPING DOLLY WITH SPEED ADJUSTABLE | HYDRAULIC POWER STATION |

|

|

| KN500/KN630 WELDING POWER SOURCE | WELDING FLUX RECYLCE DEVICE |

|

LPW-340/12000 LIGHTING POLE SHUT WELDING MACHINE: MAX WELDING DIAMETER:340MM MAX WELDING LENGTH:12M MAX WELDING WALL THICKNESS:6MM |

|

|

LPW-450/14000 LIGHTING POLE SHUT WELDING MACHINE: MAX WELDING DIAMETER:450MM MAX WELDING LENGTH:14M MAX WELDING WALL THICKNESS:6MM |

LPW-500/12000 LIGHTING POLE SHUT WELDING MACHINE:

MAX WELDING DIAMETER:500MM

MAX WELDING LENGTH:12M

MAX WELDING WALL THICKNESS:8MM

LIGHT POLES BEFORE WELDING

LIGHT POLE AFTER WELDING

FINAL WELDING QUALITY

PARAMETERS OF LIGHT POLE WELDING MACHINE|LIGHT POLE SEAM WELDING MACHINE

NAME

UNIT

LPW-340/12000

LPW-450/12000

LPW-500/12000

Ø60-340

Ø70-340

Ø200-340

Ø60-450

Ø70-450

Ø200-450

Ø60-500

Ø70-500

Ø200-500

MAX WORKALBE DIAMETER

MM

340

450

500

MIN WORKABLE DIAMETER

MM

60

60

60

MAX WELDING LENGTH

M

12 OR CUSTOMERIZED

12 OR CUSTOMERIZED

12 OR CUSTOMERIZED

WELDING POWER SOURCE

KN600

KN600

KN600

WELDING WIRE

MM

1.0-1.2-1.6

1.0-1.2-1.6

1.0-1.2-1.6

WELDING THICKNESS

MM

2.5-3

2.5-4

2.5-6

2.5-3

2.5-4

2.5-8

2.5-3

2.5-4

2.5-8

WELDING SPEED

M/MIN

1.1-2

1.1-2

1.1-2

PULLING DOLLY MOTOR

KW

4

4

4

PUMP MOTOR

KW

4

4

4

GROSS WEIGHT

KG

6300

6500

6800

OVERALL SIZES

M

26X1.8X1.8

26X1.9X1.9

26X2.0X2.1